Surface & Interface Mechanics

Research Direction: Theoretical calculation research on the friction behavior of two-dimensional material interfaces

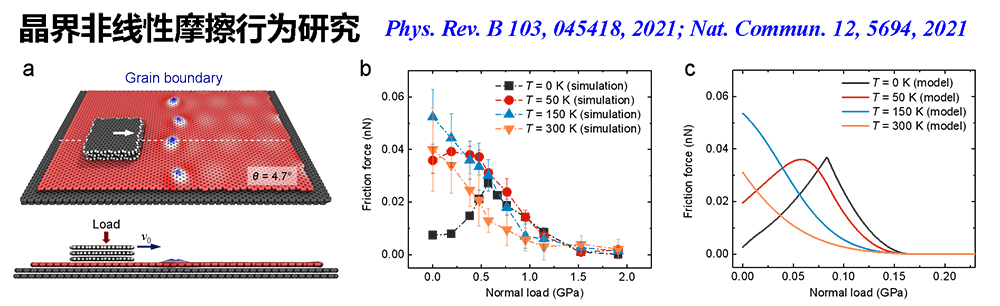

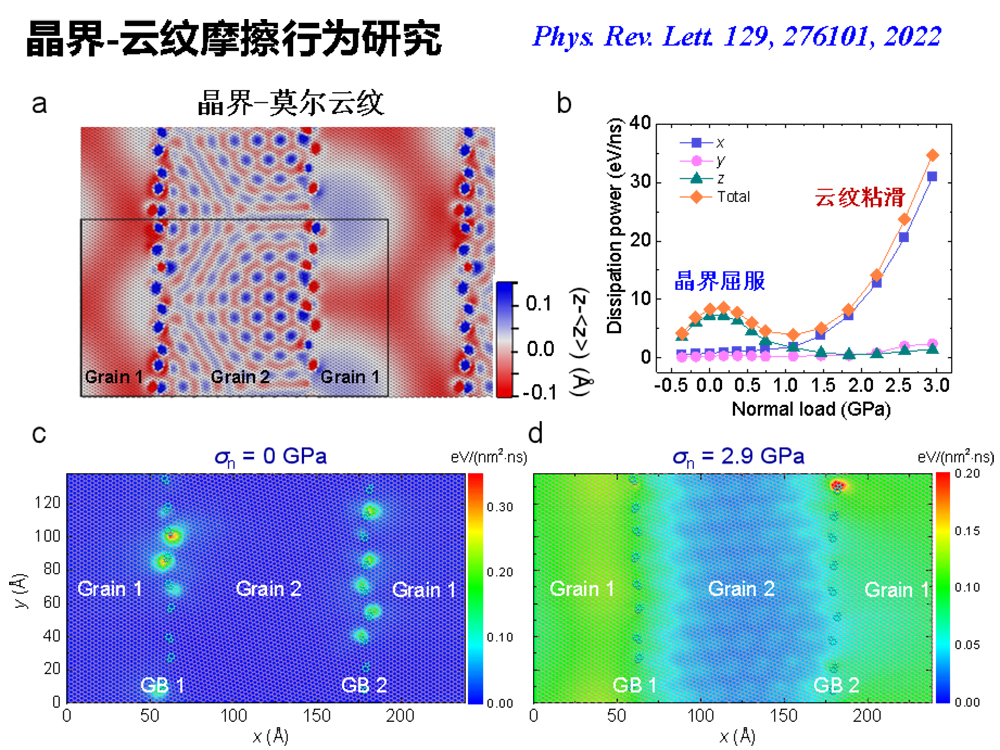

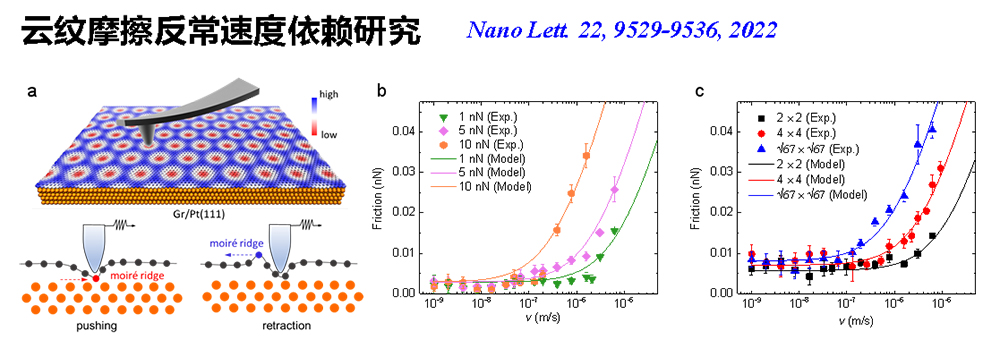

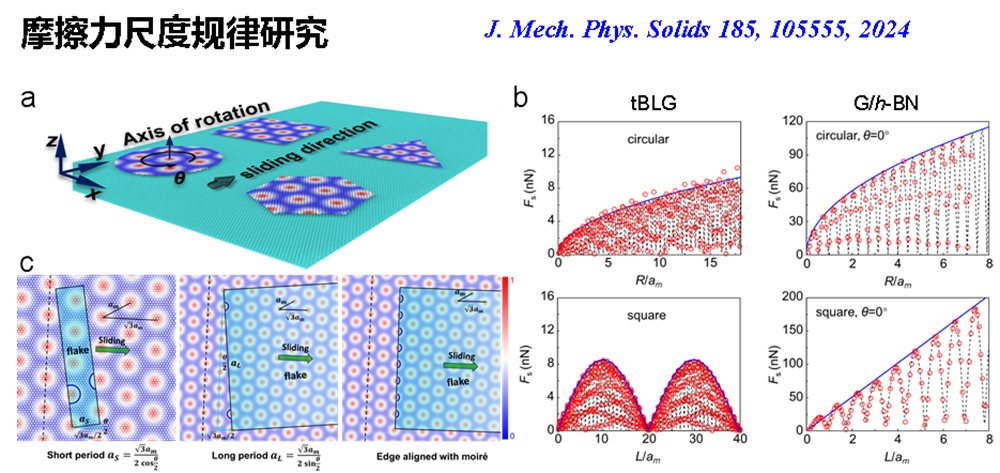

Structural superlubricity (SSL) refers to a state of near-zero friction and wear between two surfaces due to lattice mismatch. Two-dimensional materials have attracted extensive attention from the scientific and industrial communities due to their unique anisotropy of physical properties (strong intra-layer covalent bonding and weak inter-layer van der Waals interactions) and exhibit naturally excellent structural superlubricity. However, the structural superlubricity based on two-dimensional materials is currently limited to the micro-nanoscale, and how to achieve structural superlubricity at a larger scale has become a research bottleneck. With the increase size, the coupling of factors such as grain boundaries, Moiré patterns, and elastic deformation introduces new energy dissipation channels, which significantly affects the interface friction behavior and leads to superlubricity failure. In this regard, it is of great scientific significance and practical application value to carry out relevant mechanistic research based on large-scale precise computational simulation and theoretical analysis.

In view of this, our research group is conducting theoretical computational studies on the tribological behavior of interfaces in two-dimensional materials, with specific research directions including:

1. Frictional energy dissipation mechanism of grain boundaries and Moiré patterns.

2. Size dependence of static/kinetic friction force and theoretical models.

3. Anisotropic interlayer force field and multi-scale calculation method.

4. Through extensive molecular dynamics simulations coupled with theoretical analysis, we have successfully uncovered the energy dissipation mechanism at polycrystalline interfaces. We have detailed the non-monotonic grain boundary friction forces and the stick-slip phenomenon, and proposed a corresponding grain boundary friction model which has been experimentally validated. Additionally, we have delineated the mechanisms behind dislocation compensation, pinning effects, and the peculiar velocity-dependent friction at single crystal interfaces, leading to the formulation of a universal scaling rate theoretical model. Furthermore, we have developed an accurate anisotropic interlayer force field capable of precisely depicting the transition metal sulfide system. We explained the physical mechanism of multi-factor coupling affecting the friction of two-dimensional material interfaces, provided theoretical guidance for the design of large-scale superlubricity systems, and laid the foundation for further research on multi-scale friction behavior at interfaces.

Representative research results:

1. X. Gao, W. Ouyang, O. Hod, and M. Urbakh*, Mechanisms of Frictional Energy Dissipation at Graphene Grain Boundaries, Phys. Rev. B. 103, 045418 (2021).

http://doi.org/10.1103/PhysRevB.103.045418 View File

2.X. Gao, W. Ouyang, M. Urbakh*, and O. Hod, Superlubric Polycrystalline Graphene Interfaces, Nat. Commun. 12, 5694 (2021).

https://doi.org/10.1038/s41467-021-25750-w View File

3.X. Gao, M. Urbakh*, and O. Hod, Stick-Slip Dynamics of Moiré Superstructures in Polycrystalline 2D Material Interfaces, Phys. Rev. Lett. 129, 276101 (2022).

http://doi.org/10.1103/PhysRevLett.129.276101 View File

4.Y. Song#, X. Gao#, A. Hinaut, S. Scherb, S. Huang, T. Glatzel, O. Hod, M. Urbakh*, and E. Meyer*, Velocity Dependence of Moiré Friction, Nano Lett. 22, 9529-9536 (2022).

http://doi.org/10.1021/acs.nanolett.2c03667 View File

5.W. Yan#, X. Gao#, W. Ouyang*, Z. Liu*, O. Hod, and M. Urbakh, Shape-Dependent Friction Scaling Laws in Twisted Layered Material Interfaces, J. Mech. Phys. Solids. 185, 105555 (2024).

http://doi.org/10.1016/j.jmps.2024.105555 View File

Research direction: Viscoelastic friction, interface wetting and friction regulation

Due to its unique material properties, viscoelastics are widely used in equipment seals, tires, wipers, soft robots and medical devices. The requirements for the contact and friction behavior of viscoelastic materials in different application backgrounds are also different, and the different requirements for the service performance of viscoelastics in various fields are essentially the study of viscoelastic contact interface problems.

The research mainly includes:

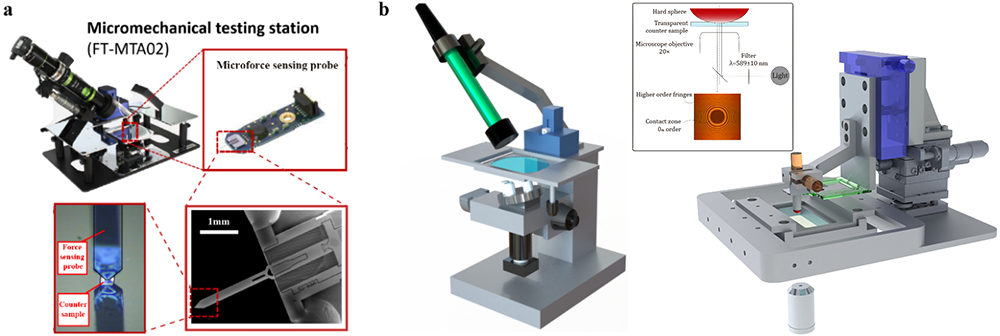

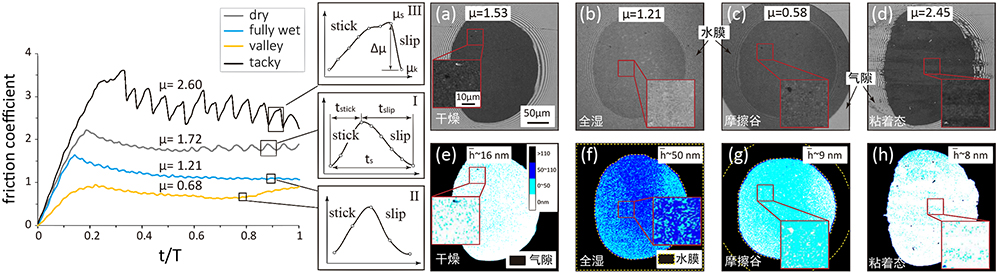

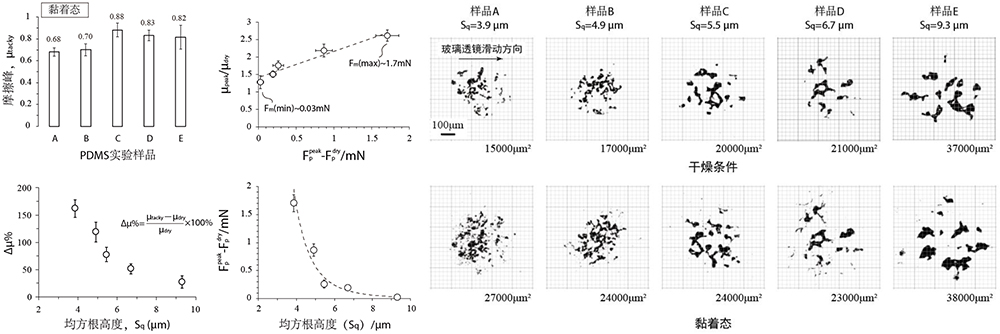

1. Measurement of adhesion and friction behavior of viscoelastic contact interface, real-time observation of contact morphology through in-situ measurement technology combined with optical interferometry

2. Characterization and measurement of surface morphology and wettability using confocal microscope, atomic force microscope and other equipment

3. Characterization of contact profile, real contact area and water film thickness based on image processing, MATLAB calculation analysis and other means

4. Exploration of the regulatory mechanism of surface material and structural characteristics on the adhesion and friction behavior of viscoelastic contact interface

Representative research results:

1. Gao T, Ye J, Zhang K, Liu X, Zhang Y, Liu K. Role of capillary adhesion in the friction peak during the tacky transition. Friction 2021.

https://doi.org/10.1007/s40544-021-0524-2. View File

2.Gao T, Liu K, Zhang K, Song Q, Ye J, Liu X. Transient High Friction Dominated by High Shear Strength Residual Water Film. Tribol Lett 2022;70:29.

https://doi.org/10.1007/s11249-022-01569-4. View File

3.Gao T, Zhang K, Liu X, Liu K, Ye J. Linking macroscale frictional properties to nanoscale water capillary bridges. Tribol Int 2022;174:107696.

https://doi.org/10.1016/j.triboint.2022.107696. View File

4. Gao T, Zhang K, Wang Y, Liu K, Liu X, Ye J. Contribution of meniscus force to friction of multi-asperity sliding contact. Tribol Int 2023;177:107994.

https://doi.org/10.1016/j.triboint.2022.107994. View File

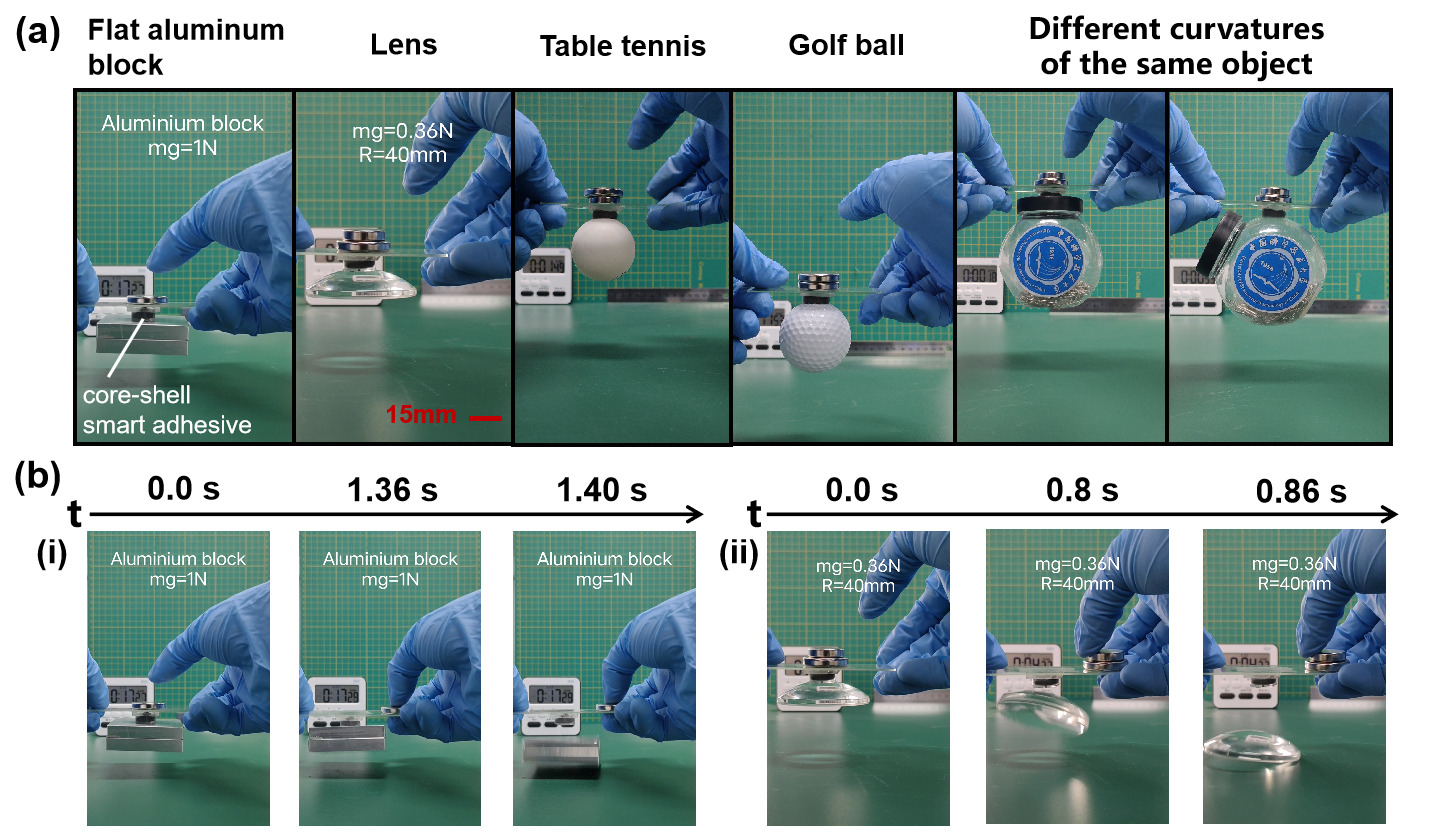

Research Focus: Structural Design and Performance Regulation of Controllable Adhesive Materials

Controllable adhesion refers to the ability of adhesive materials to vary their adhesive force and switch between adhesion and detachment in a controlled manner. In practical applications, the processes of adhesion and detachment are crucial for controlling specific objects. Therefore, adhesive materials need to exhibit strong adhesion during attachment and easy detachment during release, facilitating effective control of the target object and enabling reuse. For instance, geckos demonstrate rapid adhesion and detachment during predation and escape by applying pre-pressure and tangential dragging on their setae tips to achieve maximum tangential frictional adhesion, followed by peeling at a certain angle to reduce tangential adhesion for detachment. Our research focuses on the following key areas:

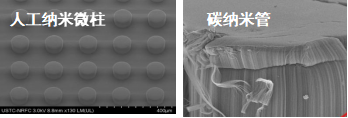

Bio-inspired Design: We employ biomimetic approaches to design and fabricate artificial microstructures that emulate the morphology and arrangement of surface microstructures found in biological organisms such as geckos and ladybugs. Using advanced nanomanufacturing techniques and material engineering methods, we create microstructured materials with the desired shapes and properties. These materials may include carbon nanotubes, magnetic materials, and others to ensure superior adhesive performance and magnetic responsiveness. The microstructures are designed with specific shapes and sizes to maximize van der Waals forces, achieving efficient adhesion on various surfaces.

Magnetic Field Regulation Technology: We utilize magnetic materials and magnetic field regulation techniques to precisely control adhesive behavior. By applying an external magnetic field, we can adjust the adhesive force and release force of the adhesive materials, enabling controllable adhesion and detachment on different surfaces. This expands the application scope and functionality of adhesive technologies.

Overall, our research aims to design and develop advanced adhesive materials that exhibit stable adhesion to multi-curved objects, active release, and rapid response. Through the integration of biomimetic design and magnetic field regulation, we strive to enhance the performance and versatility of controllable adhesive materials for a wide range of applications.

Representative research results:

1.Yang, X., Zhong, H., Zhang, P., Wang, T., Zhang, Y., Gu, P., & Zhao, Y. (2021). Ladybug Inspired Double‐Layered Adhesive with Enhanced Robustness of Surface Roughness. ChemistrySelect, 6(4), 640-646.

https://doi.org/10.1002/slct.202004610 View File

2.Wang, Tao, et al. Rapidly switchable double-layered adhesive modified by magnetic field. Chemical Engineering Journal 438 (2022): 135441.1.

https://doi.org/10.1016/j.cej.2022.135441 View File

Research direction:Study on the performance, design and manufacture of dry adhesive materials

Dry adhesive materials are mainly made of polymers, relying on van der Waals forces rather than chemical bonds to form repeatable adhesion with the target object without damaging the material surface or leaving residue. Since van der Waals forces are ubiquitous, there is no special requirement for the type of target object material. However, due to the stress concentration at the edge of the interface and the roughness of the target surface deteriorate the adhesion performances, it is still a challenge to manufacture adhesive materials that can produce reliable and high-strength adhesion. On the other hand, dry adhesive materials are different from traditional adhesives. Their main purpose is to serve as mechanical claws or the gecko-like robot feet, which require repeated bonding and detachment. Therefore, there has always been a high demand for adhesive materials with controllable adhesion. Therefore, the main research direction of adhesive materials is to pursue intelligent adhesive materials with controllable adhesion that have high adaptability to rough surfaces.

Research content includes:

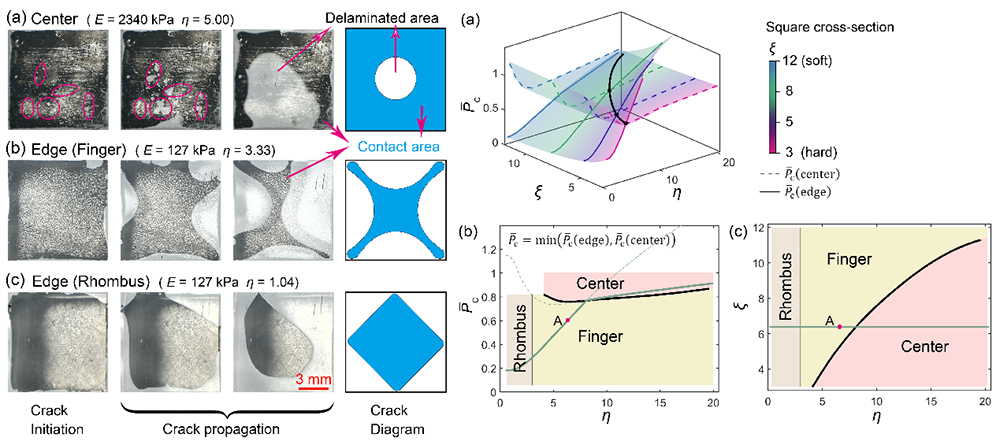

1. Combining experimental and simulation results to determine the stress distribution, delamination mode and pull-off force influencing parameters of the elastomer adhesion interface.

2. Based on the interface elastic energy and surface energy characteristics, analyze the adaptability of the elastomer to the rough substrate.

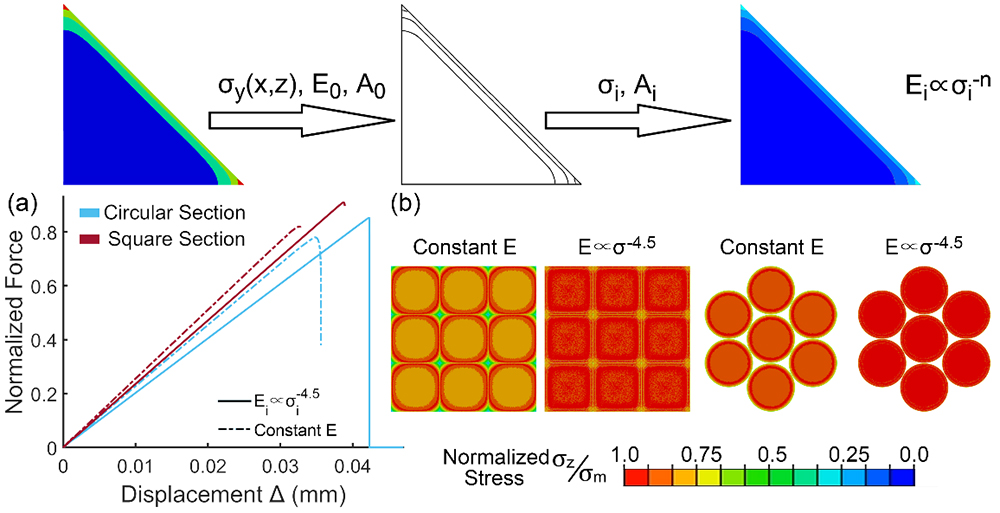

3. Based on the finite element analysis, optimize the structure and modulus distribution of the adhesive material.

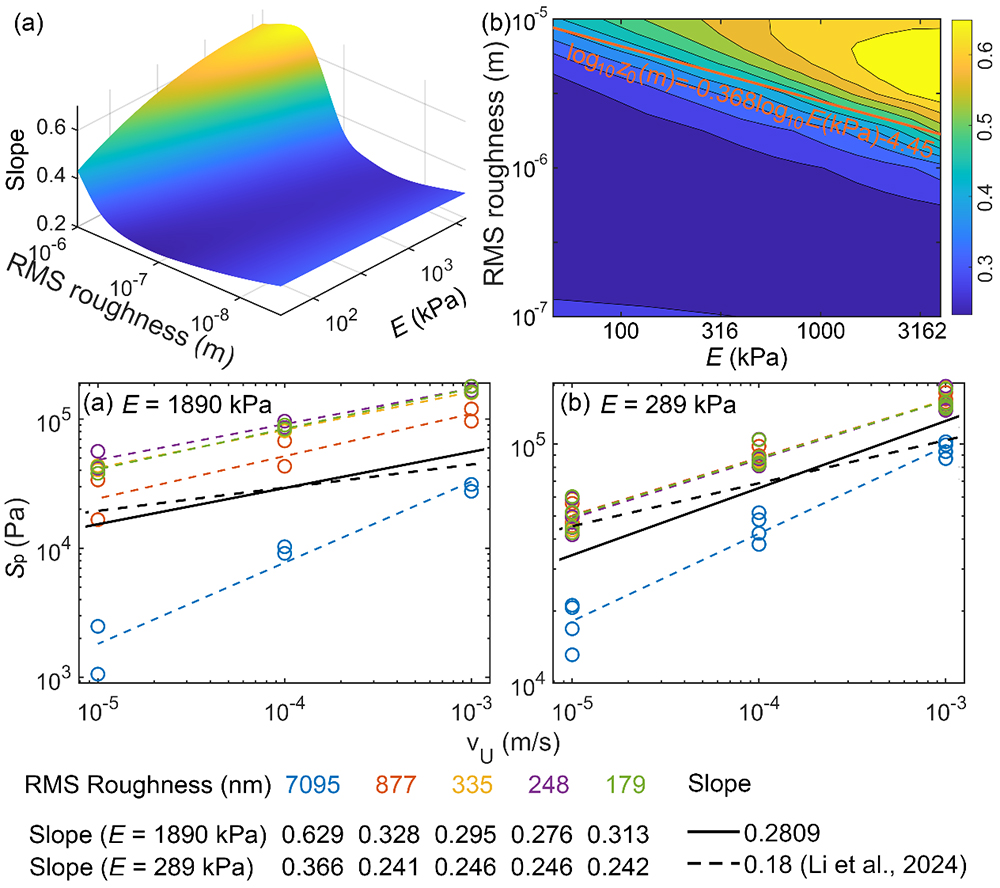

4. Based on the energy dissipation at the crack tip, analyze the effect of the pulling speed on the pull-off force of the adhesive material.

Delamination modes and pull-off forces of square cross-section elastic bodies

Adjust the transverse modulus distribution of the elastic body to increase the pull-off force

Effect of pulling speed on the pull-off force of adhesive materials on rough surface

List of achievements:

1.Chen, ZiJian, Cheng, Gang, Zhu, YinBoWu, HengAnDong, ErBaoGu, PingZhao, Yang. Biomimetic polydimethylsiloxane (PDMS)/carbon fiber lamellar adhesive composite in thermal vacuum environment[J]. International Journal of Adhesion & Adhesives, 2021, 105(1).

https://doi.org/10.1016/j.ijadhadh.2020.102778 View File

2.Chen, Z., Zhao, Y., Wu, X., & Gu, P. Interface Stress Uniformity Design of Elastomer Adhesives. Advances in Transdisciplinary Engineering, 2023, 37, 364–371.

https://doi.org/10.3233/ATDE230161 View File

Current Location:

Current Location: