Nano Composites

Nanocomposite Materials - 3D Printing

Research Direction: Advancement of 3D/4D Printing Technologies for Nanocomposite Materials and the Creation of Innovative Equipment.

Our research team is dedicated to pioneering work in the nanocomposite materials sector, focusing on the development of novel materials, processes, functionalities, and machinery. Our specific research avenues are as follows:

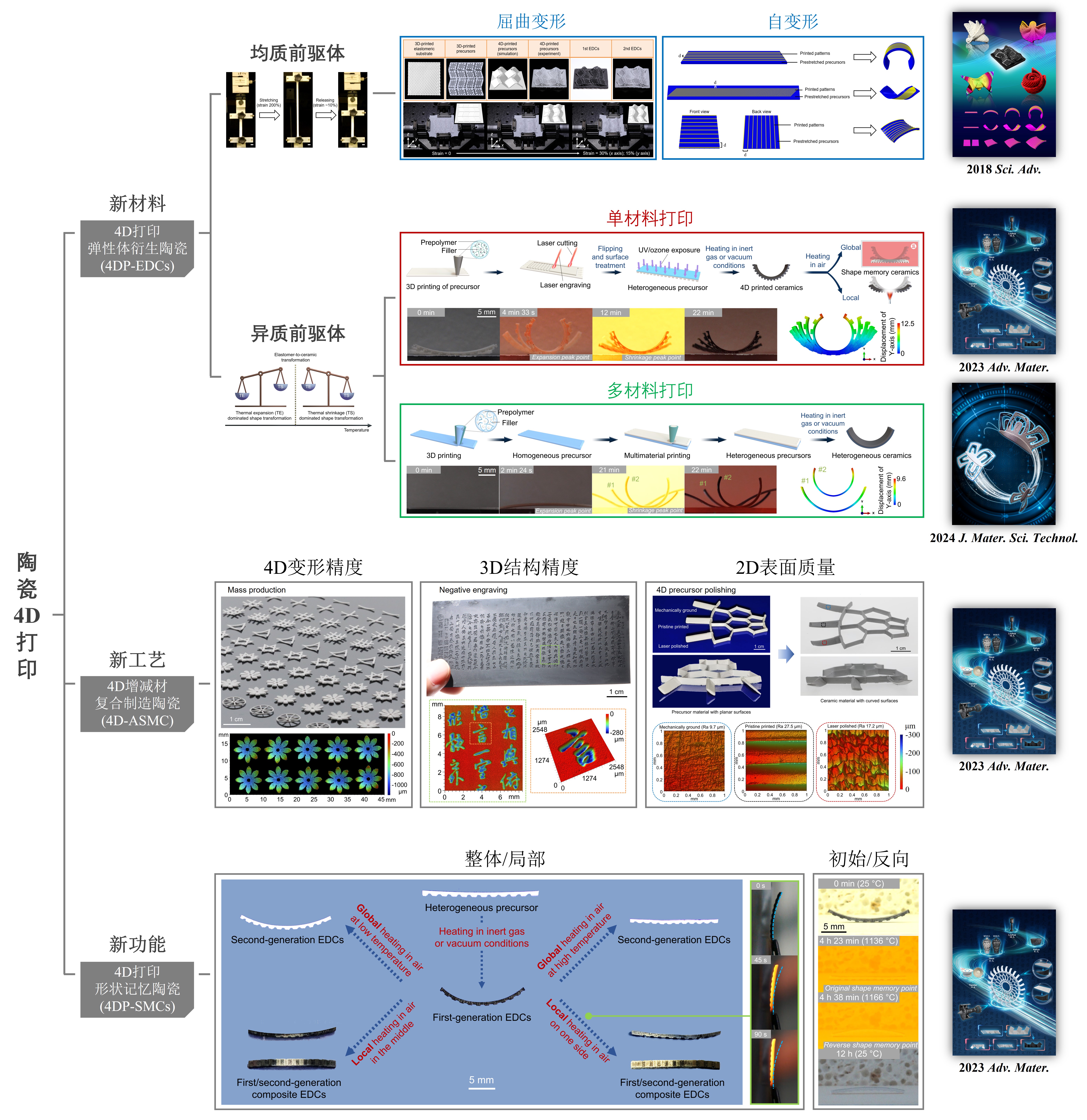

1.Development of materials specifically for 4D printing, optimization of molding processes, design of deformation mechanisms, and control of mechanical behavior.

2.Customization and application demonstration of 3D/4D printed component performance and functionality.

3.Development of innovative printing equipment for nanocomposite materials.

List of representative papers(1: co-first author; *: corresponding author):

1.Guo Liu, Yan Zhao, Ge Wu, Jian Lu*. Origami and 4D printing of elastomer-derived ceramic structures, Science Advances. 4, 8, eaat0641, 2018.

https://doi.org/10.1126/sciadv.aat0641 View Files Appendix

2.Guo Liu, Xiaofeng Zhang, Xinya Lu, Yan Zhao, Zhifeng Zhou, Jingjun Xu, Jianan Yin, Tao Tang, Peiyu Wang, Shenghui Yi, Jiafeng Fan, Xueshi Zhuo, Yu Hin Chan, Wui Leung Wong, Haidong Bian, Jun Zuo, Yu Dai, Jian Wu, Jian Lu*. 4D additive–subtractive manufacturing of shape memory ceramics, Advanced Materials. 35, 39, 2302108, 2023. (Back Cover)

https://doi.org/10.1002/adma.202302108 View Files Appendix

3.Guo Liu1, Xinya Lu1, Xiaofeng Zhang1, Yan Zhao, Shenghui Yi, Jingjun Xu, Yuqi Zhan, Jianan Yin, Chengcheng Feng, Zhifeng Zhou, Peiyu Wang, Zhou Chen, Yunhu He, Siyao Chen, Pengchao Liu, Jun Zuo, Yu Dai, Jian Wu, Sida Liu, Jian Lu*. 3D/4D additive–subtractive manufacturing of heterogeneous ceramics, Journal of Materials Science and Technology.201, 210-221, 2024. (Cover)

https://doi.org/10.1016/j.jmst.2024.02.069. View Files Appendix

4.Guo Liu1, Xiaofeng Zhang1, Xuliang Chen1, Yunhu He1, Lizi Cheng, Mengke Huo, Jianan Yin, Fengqian Hao, Siyao Chen, Peiyu Wang, Shenghui Yi, Lei Wan, Zhengyi Mao, Zhou Chen, Xu Wang, Zhaowenbo Cao, Jian Lu*. Additive manufacturing of structural materials, Materials Science & Engineering R-Reports. 145, 100596, 2021. (ESI Highly Cited Papers)

https://doi.org/10.1016/j.mser.2020.100596 View Files Appendix

5.Guo Liu1, Yunhu He1, Pengchao Liu1, Zhou Chen, Xuliang Chen, Lei Wan, Ying Li, Jian Lu*. Development of bioimplants with 2D, 3D, and 4D additive manufacturing materials, Engineering. 6, 11, 1232-1243, 2020.

https://doi.org/10.1016/j.eng.2020.04.015 View Files Appendix

6.Jia-Feng Fan1, Guo Liu1, Xue-Shi Zhuo1, Xiao-Feng Zhang*, Jun-Li Feng, Wo Jiang, Yan-Qing Jiang, Ju-Hang Yin, Bing He, Yong-Jun Hu, Rong-Jiu Li, Shuang-Quan Guo, Huan-Tao Chen, Chun-Ming Deng, Min Liu, Ke-Song Zhou*. In-situ reaction synthesis Al2O3 overlay modified 7YSZ TBC for NaCl hot corrosion, Ceramics International. 47, 16, 22404-22415, 2021.

https://doi.org/10.1016/j.ceramint.2021.04.250 View Files Appendix

7.Xueqin Zhang, Ruyue Su, Xiong Gao, Jingyi Chen, Guo Liu*, Rujie He*, Ying Li. Circumventing the brittleness of 3D-printed Al2O3 cellular ceramic structures via compositing with polyurea, Rare Metals. 2024.

https://doi.org/10.1007/s12598-024-02850-2 View Files Appendix

8.Xinya Lu1, Guo Liu1, Jian Lu*. Development of ceramic 3D/4D printing in China, Additive Manufacturing Frontiers. 200158, 2024.

https://doi.org/10.1016/j.amf.2024.200158 View Files Appendix

Patent:

1.Jian Lu, Guo Liu. In-situ 4D printing of high-temperature materials,On January 2, 2024, patent number US11858200B2 was authorized.

2.Jian Lu, Guo Liu. Method for constructing a printed ceramic object and a ceramic object constructed by the same,On August 31, 2021, patent number US11104030B2 was authorized.

3.Jian Lu, Guo Liu. System and method for four-dimensional printing of ceramic origami structures,On August 13, 2019, patent number US10377076B2 was authorized.

4.Jian Lu, Guo Liu, Yan Zhao. System and method for four-dimensional printing of elastomer-derived ceramic structures by self-forming method,On July 20, 2021, patent number US11065781B2 was authorized.

5.Jian Lu, Guo Liu, Yan Zhao. Systems and method for four-dimensional printing of elastomer-derived ceramic structures by compressive buckling-induced method,On May 11, 2021, patent number US11000991B2 was authorized.

6.Lu Jian, Liu Guo. In-situ 4D printing of high-temperature materials, September 5, 2022, authorized patent number ZL 2022 1 1077511.4.

7.Lu Jian, Liu Guo. Method for constructing printed ceramic objects and ceramic objects constructed thereby, May 24, 2022, authorized patent number ZL 2019 1 0483910.2.

8.Lu Jian, Liu Guo. Method for constructing four-dimensional printed ceramic objects, May 13, 2022, authorized patent number ZL 2018 1 0852295.3.

9.Lu Jian, Liu Guo, Zhao Yan. Self-deformation 4D printing of elastomer-derived ceramics, April 26, 2022, authorized patent number ZL 2019 1 0501955.8.

10.Lu Jian, Liu Guo, Zhao Yan. System and method for four-dimensional printing of elastomer-derived ceramic structures by compression buckling-induced method, July 22, 2022, authorized patent number ZL 2019 1 0517900.6.

Nanocomposite materials - ultra black materials

Research direction:Research on the design, preparation, properties and application of carbon nanocomposite ultra-black materials

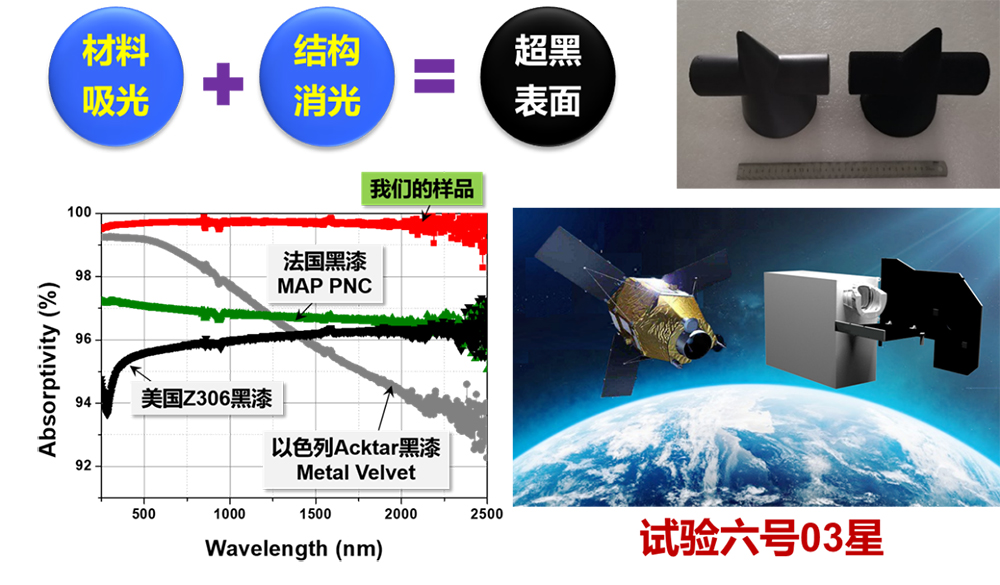

Ultra-black material is a new type of structured surface material with extremely high light absorption rate (generally higher than 98%) within a certain spectral range. Its absorption characteristics are close to those of a black body, and there is an urgent application demand in a wide range of fields from high-end optical equipment to solar thermal conversion equipment. However, the current ultra-black material preparation technology is relatively complex, the processing conditions are relatively harsh, and precise and expensive processing equipment is required. It is not suitable for coating on large-area workpieces or complex curved surfaces. At the same time, it is still a huge challenge to obtain ultra-blackness and mechanical robustness in a wider spectral range. Therefore, the development of an ultra-black material with mild preparation conditions, large-area preparation, excellent light absorption performance, and good long-term performance is of great significance for practical applications.

In view of this, our research group conducts research on the design, preparation, performance and application of carbon nanocomposite ultra-black materials. The specific research directions include:

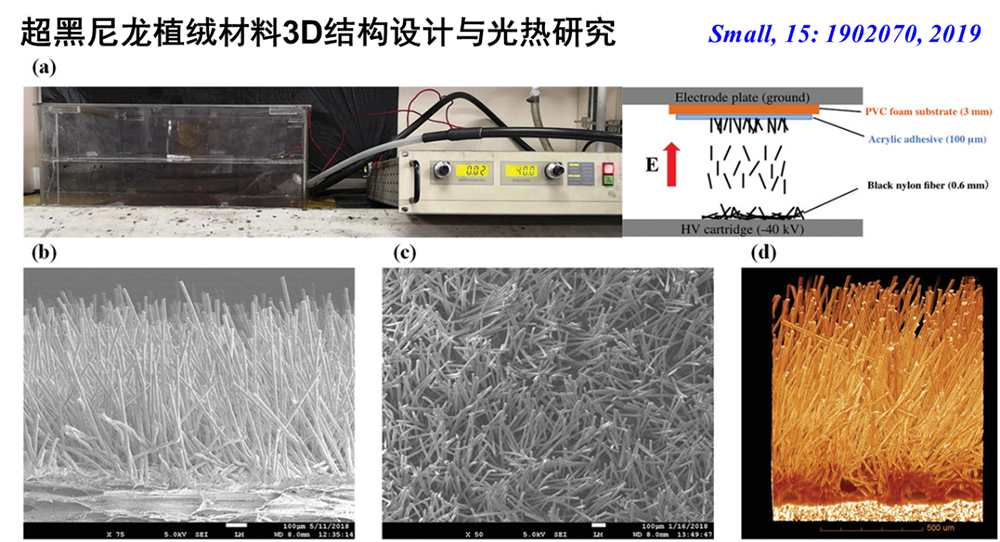

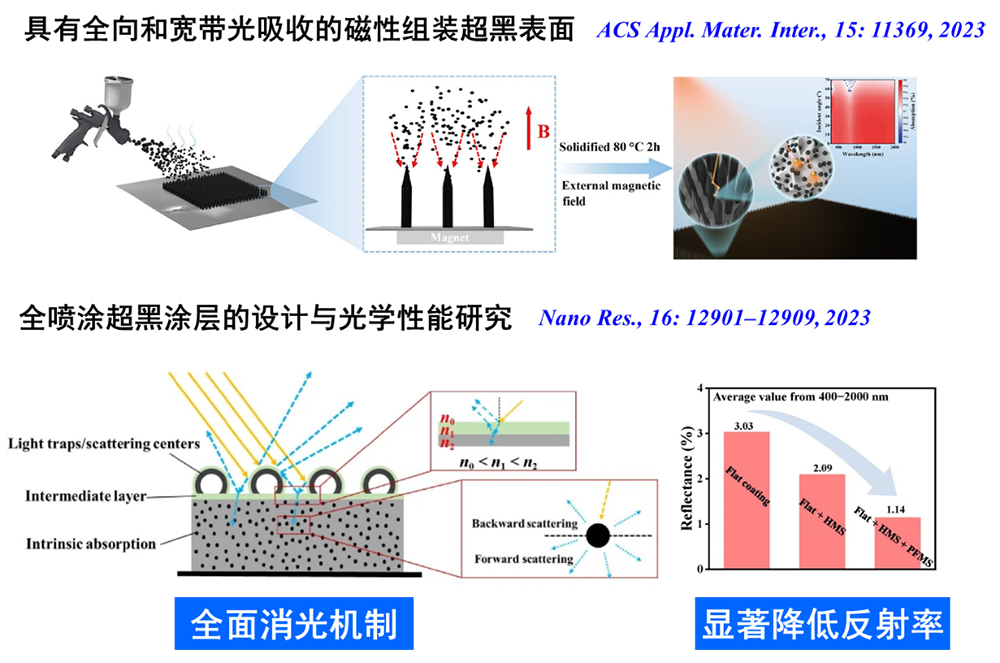

1. Design and construct arrays of carbon tubes, carbon fibers, polymer fibers, etc. through electrostatic flocking, and design and construct ultra-black surfaces such as composite needle structures and fully sprayed ultra-black coatings through spraying, etc.

2. Characterization and measurement of structure-performance based on synchrotron radiation large scientific facilities, etc.

3. Based on the characteristics of ultra-black surfaces such as high light absorption, super hydrophobicity, and excellent photothermal conversion, explore its outstanding applications under various working conditions including space test satellite cameras, self-cleaning surfaces, solar thermal collection, and flexible airflow sensors

4. Based on the nanocomposite ultra-black material engineering laboratory, explore engineering preparation and application

Based on the intrinsic absorption of carbon nanomaterials and the synergistic effect mechanism of multiple reflection absorption of micro-nano composite structures, the research team successfully developed a nanocomposite ultra-black material, which achieved a high absorbance of 99.6% and stable omnidirectional absorption characteristics in the ultraviolet-visible-near infrared, exceeding similar international technologies. A nanocomposite ultra-black material engineering laboratory was built and large-scale engineering preparation was achieved. The service performance fully meets the needs of extreme space environments. It has been successfully applied to the Experimental No. 6 03 satellite launched on April 9, 2021 and the Sustainable Development Science Satellite No. 1 low-light camera launched on November 5, 2021, which greatly improved the detection capability of satellite optical systems for dim targets and has great application prospects in the field of deep space exploration.

List of representative achievements:

1. Li H, Shen C, Sun S, Li C, Zhang H, Zhang Z. Magnetically Assembled Ultrablack Surface with Omnidirectional and Broadband Light Absorption. ACS Appl Mater Interfaces. 2023;15:11369-78.

https://doi.org/10.1021/acsami.2c19796. View Files

2.Shen C, Li H, Sun S, Zhang H, Yan L, Zhang Z. Design and optical performance investigation of all-sprayable ultrablack coating. Nano Res. 2023;16(12):12901–9.

https://doi.org/10.1007/s12274-023-5590-5. View Files

3. Shen C, Sun S, Zhang H, Zhang Z. Bioinspired Ultrasensitive and Flexible Airflow Sensor based on Short Carbon Fiber Network. Advanced Materials Technologies. 2023;8(1):2200571.

https://doi.org/10.1002/admt.202200571. View Files

4. Zhang L, Huang Z, Cai W, Xue X, Min X, Zhang H, et al. Hairy superhydrophobic surfaces with excellent mechanical robustness, underwater stability and drag-reduction property. Prog Org Coat. 2023;174:107323.

https://doi.org/10.1016/j.porgcoat.2022.107323. View Files

5. Tu C, Cai W, Chen X, Ouyang X, Zhang H, Zhang Z. A 3D-Structured Sustainable Solar-Driven Steam Generator Using Super-Black Nylon Flocking Materials. Small. 2019;15(37):1902070.

https://doi.org/10.1002/smll.201902070. View Files

Patents:

[1] Li Huiyong, Shen Chen, Zhang Hui, et al. An ultra-black material based on magnetic field-induced self-assembly and its preparation method and application [P]. Beijing: CN202210625613.9, 2023-01-06.

[2] Shen Chen, Zhang Hui, Zhang Zhong, et al. A flexible airflow sensor and its preparation method and application [P]. Beijing: CN202110912092.0, 2022-10-14.

[3] Shen Chen, Gao Feng, Zhang Hui, et al. An interlayer modified carbon fiber composite material and its preparation method and application [P]. Beijing: CN202210233556.X, 2022-04-22.

[4] Cai Wenfu, Tu Ce, Zhang Hui, et al. A fiber array ultra-black material and its preparation method [P]. Beijing: CN201811130448.X, 2022-09-06.

[5] Tu Ce, Cai Wenfu, Zhang Hui, et al. A black body fiber flocking material and its preparation method and use [P]. Beijing: CN201811130172.5, 2022-09-06.

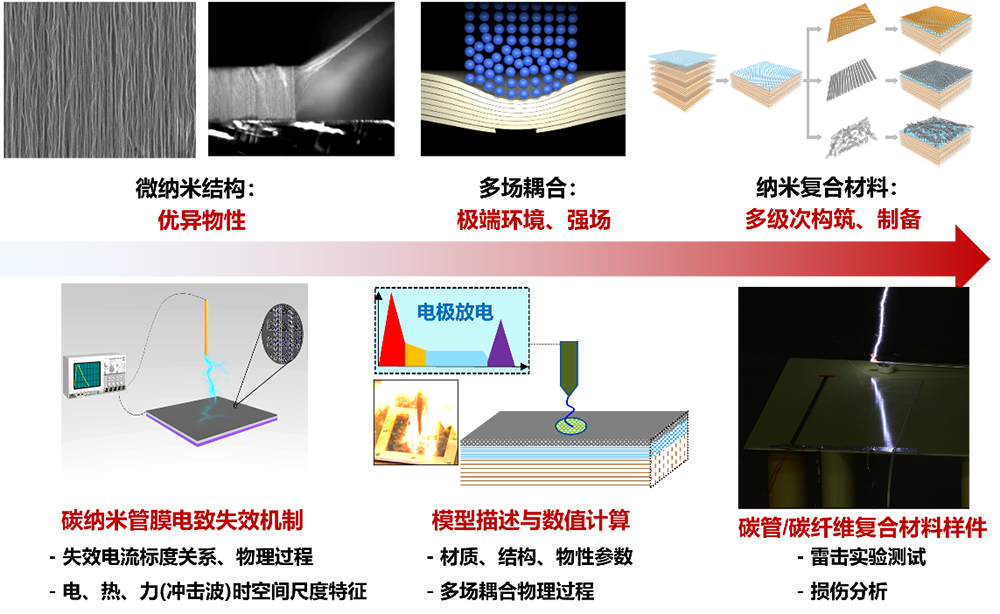

Research direction: Nanocomposite protective materials for extreme environments

In view of the urgent need for lightning strike, high-energy impact protection and anti-icing functions in my country's aerospace field, it is urgent to develop protective material structures and technologies suitable for extreme environments and long-term stable service. Carbon nanocomposites have unique advantages such as outstanding physical and mechanical properties, precise construction of micro-nano structures, and optimized design of multi-scale surfaces and interfaces, which provide innovative ideas for meeting the above needs and exploring key applications. This research group clarifies and solves common scientific and technological problems in protection mechanisms, develops structural and functional integrated design and preparation methods, and realizes typical applications in key structures such as fuselage, wing and tail leading edges, radomes, and fuel tank covers. The specific contents are as follows:

1. Design and experimental analysis of carbon nanocomposites

2. Structure-effect theory of carbon nanocomposites and prediction model of service performance

3. Analysis of key application protection performance requirements and preparation of carbon nanocomposite structural parts

4. Analysis of extreme environment protection mechanism, detection technology and performance evaluation

Based on the excellent physical properties of carbon nanomaterials, multi-level nanocomposite protective materials are constructed for extreme service environments with multi-field coupling. Relying on the University of Science and Technology of China, in cooperation with aviation companies such as AVIC Jinan Special Structure Research Institute, Shanghai Aircraft Manufacturing Co., Ltd., Hefei Aerospace Electro-Physics Technology Co., Ltd., and AVIC Xi'an Aircraft Industry Co., Ltd., it has great application prospects in the field of aircraft extreme service environment protection.

Representative Research Results:

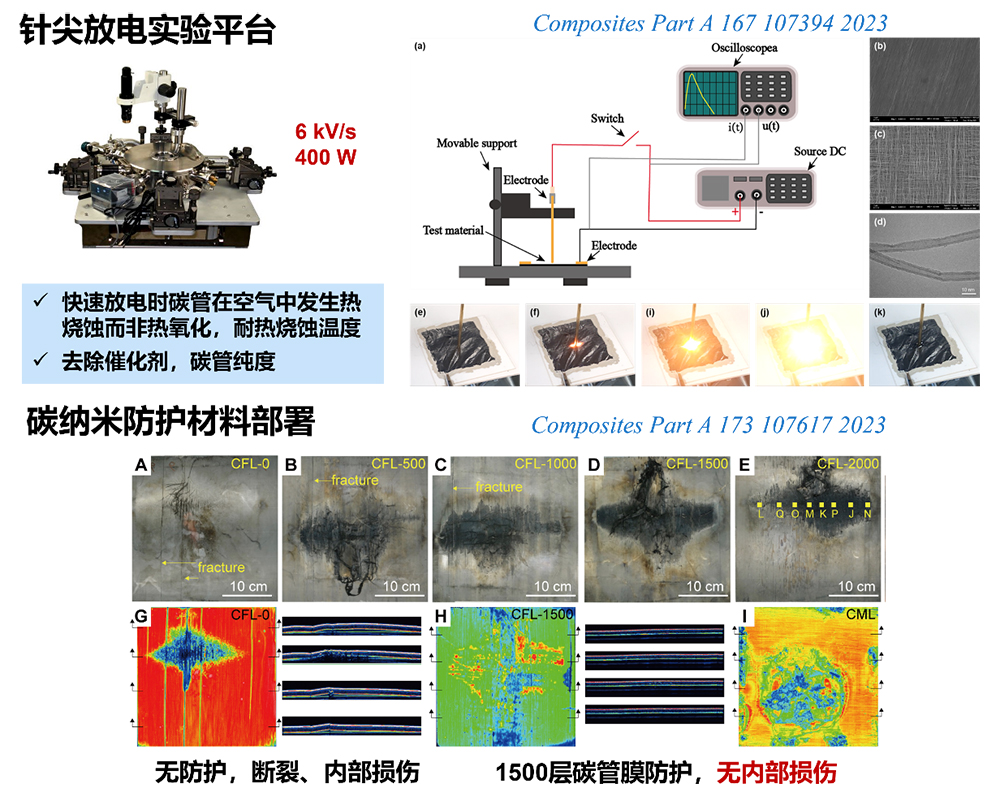

1. Bai, Y.; Zhu, M.; Wang, S.; Gao, F.; Gao, R.; Qu, Y.; Cui, X.; Wang, G.; Liu, L.; Zhang, H.; et al. Mechanism study of advanced lightning strike protection composite systems using a miniature tip discharge system. Composites Part A: Applied Science and Manufacturing 2023, 167, 107394. DOI:

https://doi.org/10.1016/j.compositesa.2022.107394. View Files

2.Bai, Y.; Zhu, M.; Wang, S.; Gao, F.; Gao, R.; Wang, C.; Wang, G.; Jin, H.; Liu, L.; Zhang, H.; et al. Superaligned carbon nanotube film/quartz fiber composites towards advanced lightweight lightning strike protection. Composites Part A: Applied Science and Manufacturing 2023, 173, 107617. DOI:

https://doi.org/10.1016/j.compositesa.2023.107617. View Files

3. Bai, Y.; Zhu, M.; Wang, S.; Liu, L.; Zhang, Z. Dynamic electrical failure of carbon nanotube ribbons. Carbon 2023, 202, 425-431. DOI:

https://doi.org/10.1016/j.carbon.2022.10.070. View Files

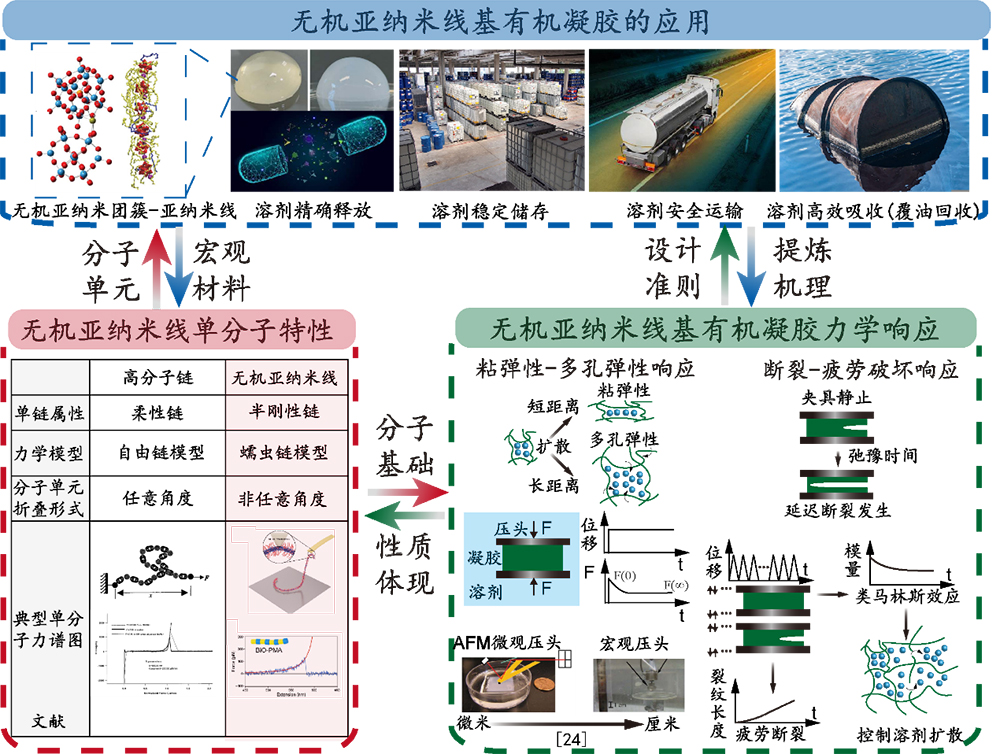

Research direction:Polymer/Polymer-like Gel

Polymer gels have been widely used in medicine and industry. Studying the toughening mechanism of polymer gels is of great significance to overcoming the bottleneck of mechanical failure in service. Inorganic sub-nanowire-based organogels are emerging materials with inorganic-organic material properties invented by Chinese scientists for the first time in 2022. Their network is a polymer-like inorganic sub-nanowire, and the dispersion medium is an organic solvent. However, inorganic sub-nanowires are semi-rigid chains, and the mechanical properties of single molecules are very different from those of polymer flexible chains. Therefore, the existing mechanical models of polymer gels cannot be directly applied to inorganic sub-nanowire-based organogels. The lack of mechanical mechanism makes it difficult to evaluate the stability of inorganic sub-nanowire-based organogels when storing and transporting hazardous reagents, and it is difficult to optimize the design to resist damage when serving in harsh environments. Our research group has conducted comparative studies on the mechanical mechanisms of polymer/quasi-polymer gels, including the following:

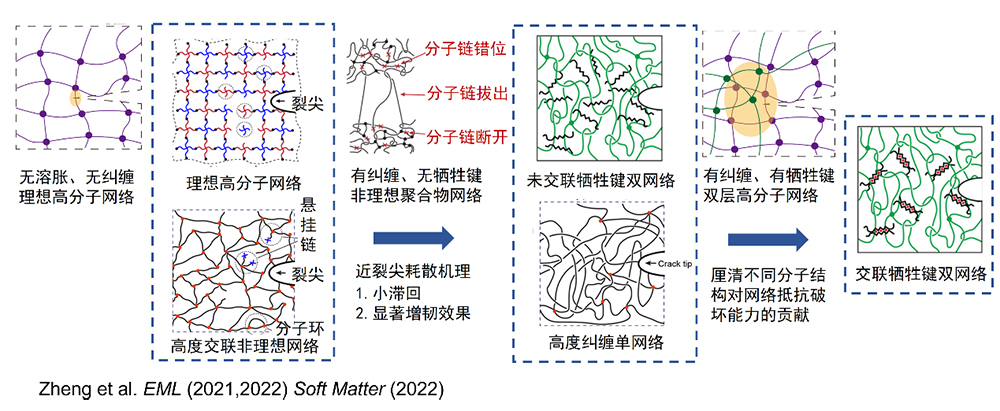

1. Toughening mechanism of polymer gel network and design of tough composite materials

2. Viscoelastic-porous elastic response mechanism of inorganic sub-nanowire-based organogels

3. Fracture-fatigue failure mechanism of inorganic sub-nanowire-based organogels

The emergence of inorganic sub-nanowire-based organogels proves that gel materials with both inorganic and organic material properties can be constructed by precisely controlling the self-assembly of inorganic clusters at the sub-nanoscale. Inorganic sub-nanowire-based organogels have broad prospects in the efficient absorption, stable storage, safe transportation and precise release of organic solvents such as gasoline and n-octane. Developing a model to describe the mechanical response of inorganic sub-nanowire-based organogels under stimulation such as solvent diffusion and mechanical load can guide the stability assessment of the gel in the storage and transportation of hazardous solvents, optimize the design of the gel in harsh environments to resist damage, and provide theoretical support for the application of the gel.

Representative Research Results:

1. Zheng, D.; Lin, S.; Ni, J.; Zhao, X. Fracture and fatigue of entangled and unentangled polymer networks. Extreme Mechanics Letters 2022, 101608. View Files

Current Location:

Current Location: